Made in Germany

When the traditional craft of the blacksmith meets cutting-edge technology – this is “Made in Germany” means.

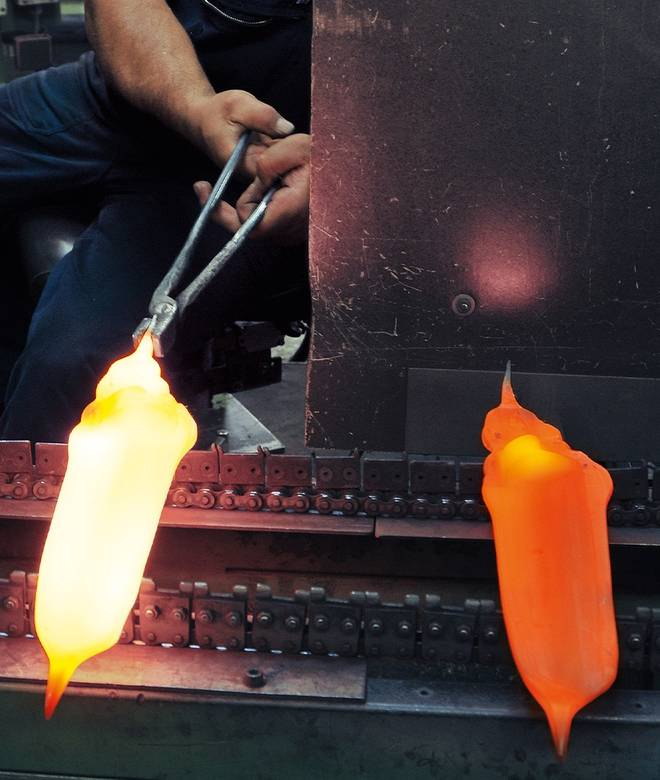

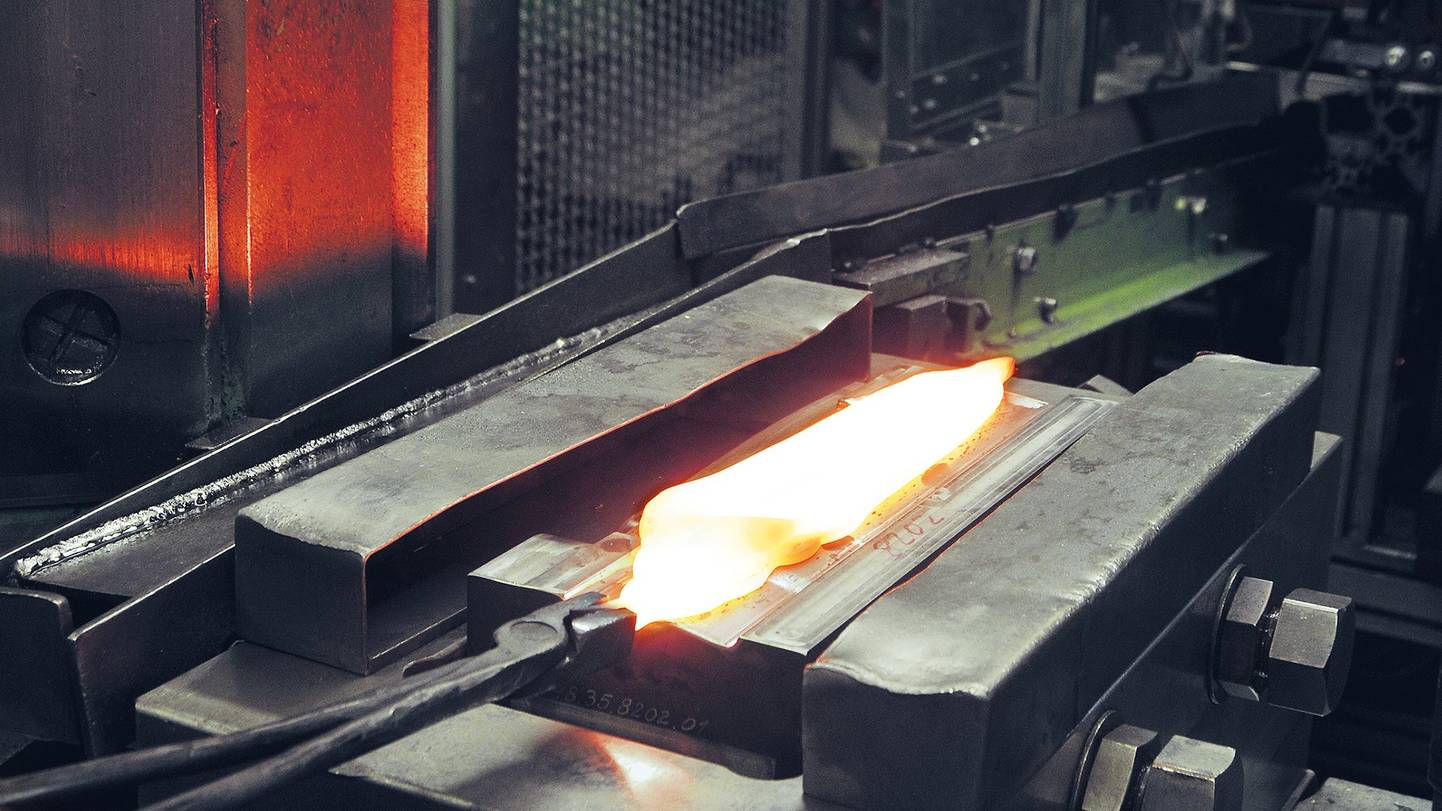

In Hayingen, a small town at the heart of the Swabian mountains, WMF operates one of Germany’s largest blade manufacturing facilities. Each year, the company’s factory produces hundreds of thousands of knives using traditional die-forging techniques. In this process, a forging hammer is used to shape the entire blade, which is made from special blade steel. Approximately 30 strictly controlled production steps are required before the customer can hold one of these premium quality knives in their hand. These include testing the raw material, packing and dispatching.

Approximately 30 strictly monitored production steps are required before the customer can hold one of these premium quality knives in their hand.

This is how WMF guarantees its high quality standards at every stage of the manufacturing process. The result is “Made in Germany” knife blades. These are phenomenally sharp and highly precise with a long-lasting cutting performance. Performance Cut technology is the link between traditional forging techniques and the latest precision technology, such as new and innovative steel finishing processes and high-precision blade sharpening techniques. The resulting knives boast an optimum cutting angle and exceptionally long-lasting sharpness.

Sharpening your knife correctly

GETTING THE ANGLE RIGHT: You should divide a large blade into three parts: the point, the middle, and the end. The ideal sharpening angle is usually 15 degrees for European knives and 10 degrees for Japanese knives. Suggestion: To get an idea of the correct angle, place two one-euro coins, (4.4 cm thick), on top of each other in a central position underneath the blade.