Feel the craftsmanship.

From fused elements to culinary excellence.

Fusiontec – A cookware revolution.

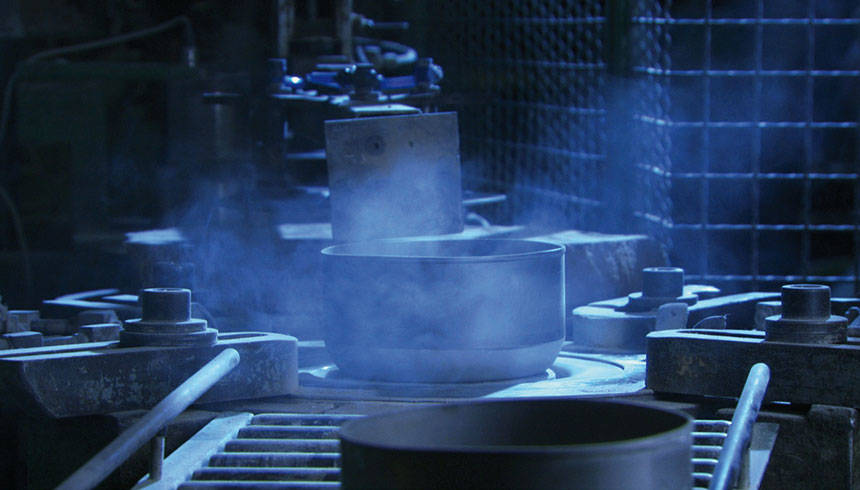

The ambitious scientists and craftsmen of Riedlingen in South Germany set out to create a super alloy offering the very best qualities of existing cookware materials all in one place. They have worked tirelessly to make it happen, perfecting their craft with no shortage of energy and passion. The result is a cookware revolution we call Fusiontec.

A special manufacturing process.

CHROMINGThe pouring rim is produced by polishing and plating process, after that it is sealed with chromium to protect it from corrosion and chipping off.

QUALITY CONTROL The handles are then assembled and a final 100% quality control is executed by hand.

The best of cookware in one high-performance material.

Fusiontec cookware by WMF brings together the speed of copper, the heat retention of cast iron, the scratch resistance of glass, the non-corrosive nature of stainless steel and the homogeneous cooking results of aluminum – all in one unique material**. The result: A fast heat-up, excellent heat distribution and retention for energy saving cooking, and flawlessly even cooking results. The extremely hard surface is robustly crafted, resistant to scratches and abrasions, exceptionally durable and dishwasher safe, all with a stylish aesthetic that’s made to last.

**based on scientific literature and internal tests, 2020

Correct use and maintenance - here's how

WMF Fusiontec Mineral

The WMF Fusiontec Mineral range is available in colors inspired by minerals and has a subtle metallic effect. The glass lid is ideal for keeping an eye on your cooking. The range is available in all standard sizes and in different colors.